Centrifugal extractor - centrifugal force

Centrifuge | liquid-liquid | Series: LX

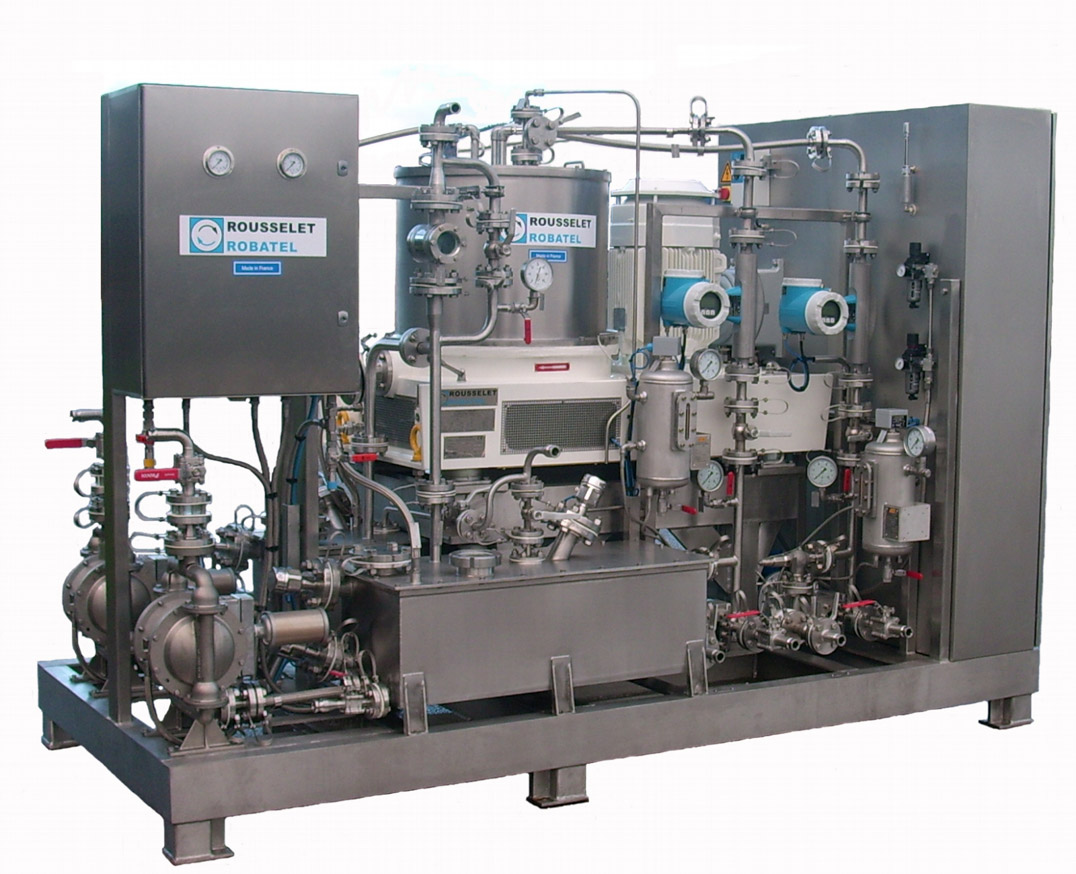

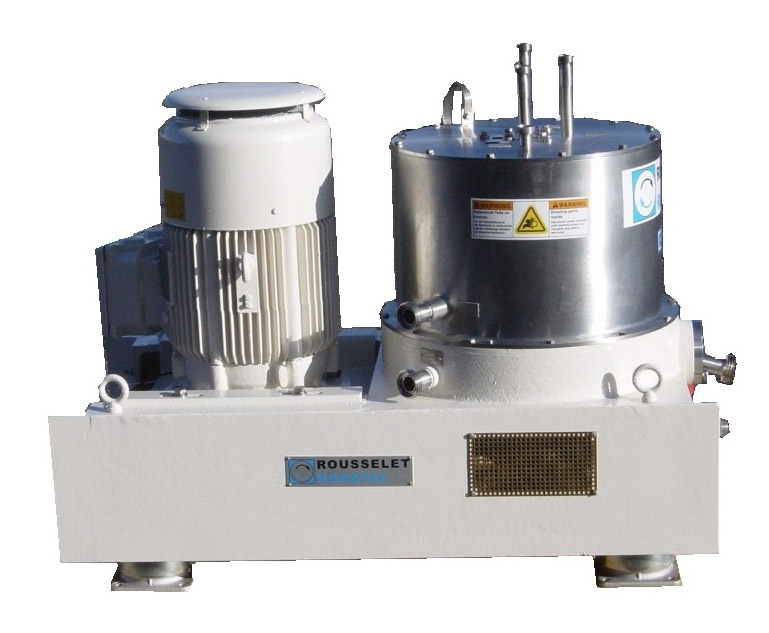

Rousselet Robatel's multistage centrifugal extractors are used in the pharmaceutical, fine chemical, food and nuclear industries.

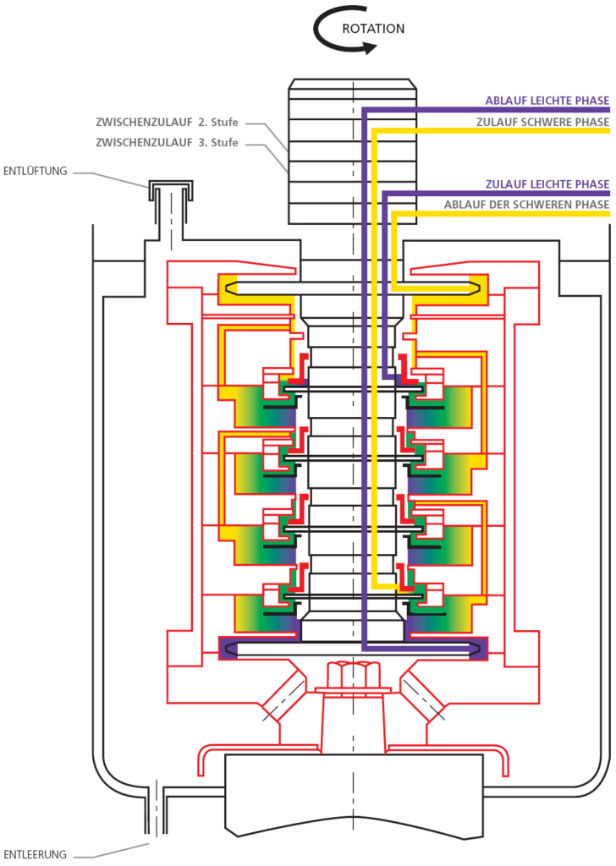

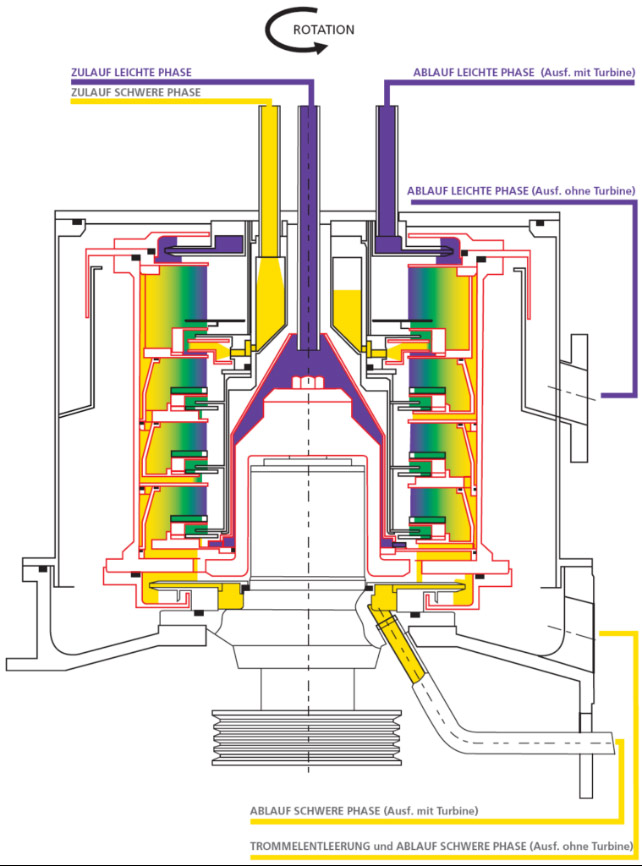

Functional description

The phase to be extracted , initially containing one or more solvates (heavy phase on the cross-sectional sketches), and an immiscible solvent of a different density (light phase on the cross-sectional sketches) flow in countercurrent into the extractor rotor, which is constructed with a stack of mechanical assemblies representing required number of separate stages.

The successive mixing and separating operations performed in each mechanical stage enable mass transfer of the dissolved solvates from the feed solution into the solvent.

Advantages

- Up to 7 stages in a single machine. Thus very high extraction efficiency.

- Each stage practically corresponds to a theoretical extraction stage.

- Low space requirement and incomparable compactness.

- The extractor can be mounted on a trolley, with the advantage of mobility.

- Very low application and maintenance costs (1 single rotor / 1 single motor).

- Centripetal turbines, which generate a delivery pressure, discharge the two separate phases into the storage tanks or auxiliary equipment (this allows several extractors to be connected in series for processes requiring a large number of stages).

Application examples

PHARMACY: Purification of active ingredients (e.g. antibiotics).

CHEMISTRY: Washing (e.g. polymers)

- Extraction (e.g. acetic acid)

- Waste water treatment (e.g. phenol extraction from aqueous phase)

PARACHEMISTRY: perfumes, aromas, essential oils...

FOOD INDUSTRY: Purification of food components (e.g. carboxylic acid)

HYDROMETALLURGY: separation or purification (e.g. precious metals)

Main construction features

All parts in contact with the product are made of stainless steel (mat. no. 1.4404) or alloys (alloy, titanium). The seals are made of PTFE.

The outer casing is mounted on a machine frame (mild steel or cast iron, with inner lining). It is equipped with all the nozzles : phase inlets and outlets, drainage nozzles to empty the drum when it is not running, inert gas and vent nozzles, ..... The machine frame is mounted on vibration dampers.

Power transmission consisting of an electric motor (sealed or gas-protected) coupled to a frequency converter. Flexible coupling as motor/rotor shaft connection (LX 120/200) or power transmission by pulleys and antistatic V-belts (LX320/360/520/570).

Bearing housing with ball bearings (LX 120/200), or roller bearings (with grease lubrication) and pneumatic lock.

Unit with CE marking. It complies with the ATEX directives.

Technical data LX series

| Type LX | Number of steps | Reel ⌀ (mm) | Contents (L) | Rotation speed (U/min) | G-number | max. Throughput (l/h) | Engine power (kW) |

|---|---|---|---|---|---|---|---|

| 124 | 4 | 120 | 0,27 | 3.600 | 30 | 0,75 | 870 |

| 126 | 6 | 120 | 0,39 | 3.600 | 30 | 0,75 | 870 |

| 204 | 4 | 200 | 1,8 | 3.600 | 300 | 1,5 | 1.449 |

| 324 | 4 | 320 | 10,2 | 3.200 | 1.500 | 5,5 | 1.832 |

| 325 | 5 | 320 | 9,3 | 3.200 | 1.300 | 5,5 | 1.832 |

| 364 | 4 | 360 | 13,6 | 3.000 | 1.800 | 7,5 | 1.811 |

| 365 | 5 | 360 | 12,6 | 3.000 | 1.500 | 7,5 | 1.811 |

| 524 | 4 | 520 | 57 | 2.000 | 6.000 | 18,5 | 1.163 |

| 525 | 5 | 520 | 54 | 2.000 | 5.000 | 18,5 | 1.163 |

| 526 | 6 | 520 | 52 | 2.000 | 4.500 | 18,5 | 1.163 |

| 527 | 7 | 520 | 49 | 2.000 | 3.500 | 18,5 | 1.163 |

| 574 | 4 | 570 | 74 | 2.000 | 8.000 | 18,5 | 1.275 |

| 575 | 5 | 570 | 70 | 2.000 | 7.000 | 18,5 | 1.275 |

| 576 | 6 | 570 | 67 | 2.000 | 6.000 | 18,5 | 1.275 |