Services

ARRGOS accompanies its customers from the first concept to the maintenance of the equipment.

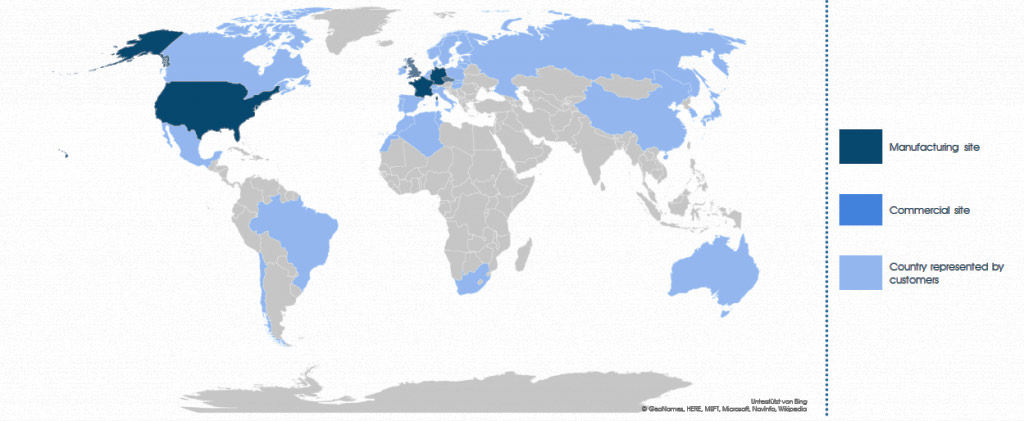

With our teams in France, Germany and worldwide, we offer:

Feasibility check

- At the Rousselet test site in Annonay: we can test the centrifuge technology with non-hazardous materials.

- On site: preliminary studies with equipment required for the customer's process.

Technical support

- More than fifteen highly qualified engineers and technicians work on continuously improving the machine design so that we can offer and deliver unique and reliable solutions for specific cutting tasks.

- Our process and mechanical engineers are on hand to assist you with set-up and provide technical advice on new applications.

- Our engineering department can draw sketches and/or perform some initial calculations to check the mechanical and electrical possibilities.

Optimisation

Sample and pilot tests are carried out at Rousselet or at the customer's site to evaluate performance on an industrial scale.

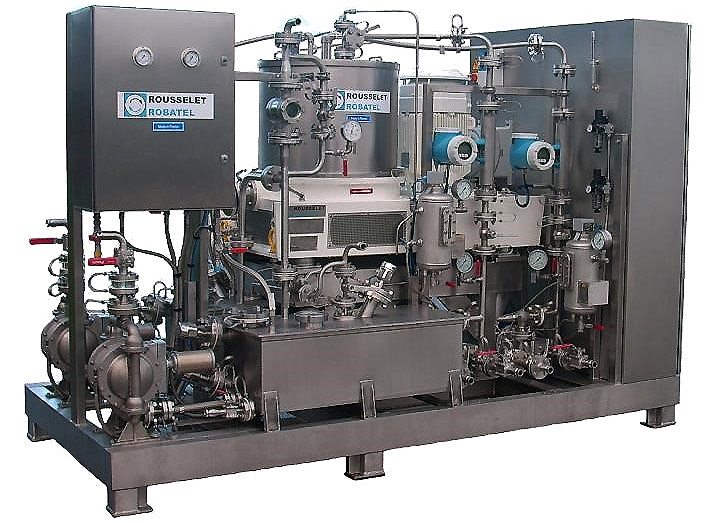

Rousselet Robatel has a wide range of equipment in stock for you to rent or buy, for on-site testing and temporary production.

Inspections of production equipment, particularly centrifuges, are recommended to ensure optimum installation, safety and efficiency.

On the basis of extensive experience and cases of damage, and taking into account accumulated experience, it is recommended that the following checks be carried out on centrifuges by qualified personnel:Check before the first commissioning

Operators must ensure that centrifuges that fall within the scope of the Machinery Ordinance are checked to ensure that they are properly installed, equipped and ready for operation before they are put into service for the first time.

The inspection before commissioning must cover the following in particular:

- Arrangement of the actuating elements of emergency switching devices (emergency stop) and main switches, leakage of substances with hazardous properties,

- Electrical equipment,

- Potentially explosive atmosphere,

- Noise during installation at the production site,

- Stability,

- Centrifuge suitable for the intended use,

- Presence of required documentation,

- Instructions for use with documentation and manufacturer's declaration,

- Register for control.

Control after a change

The operator must ensure that centrifuges which are converted by him for working procedures or supplemented by other equipment and which are intended for an operating mode not provided for in the centrifuge manufacturer's operating instructions are checked for their safe operating condition before being put into operation for the first time.

We ensure that your system operates at peak efficiency and meets safety standards.

An annual preventive maintenance and diagnostic check-up can be carried out on site by our engineers and technicians. This usually takes place during a planned shutdown.

In the accident prevention guideline, concrete statements on the necessary checks have been made on the basis of extensive experience and damage cases. We therefore recommend that you take this experience into account and have the following checks carried out on centrifuges by qualified personnel:

Check in operational state

Operators must ensure that centrifuges are inspected for operational safety at least once a year in operational condition.

During the inspection, a full inspection of all mechanical and electrical aspects of the centrifuge will be carried out.

An inspection report will be provided to the customer detailing recommendations and corrective actions with recommended spare parts or parts that need to be replaced.

The regular inspection in working order mainly refers to :

- the condition of the components and equipment,

- any modifications to the safety devices,

- integrity and effectiveness of the safety devices,

- conformity of the technical characteristics of the centrifuge with the specifications in the manufacturer's certificate,

- integrity of the control book,

- functional test of the centrifuge without feed,

- regulation of the rotation speed,

- sensor for unbalance.

Check in disassembled state

Operators must ensure that centrifuges are inspected as required, but at least every three years, when dismantled to ensure operational safety. The centrifuge shall be dismantled in such a way that inspection of the parts that ensure operational safety is possible.

The recurring inspection in the dismantled state essentially comprises:

- Visual inspection of the general condition of the equipment

- Disassembly of the bearing housing and the shaft guidance system

- Replacement of all seals and bearings of the bearing housing

- Inspection of the drives and replacement of the drive belts

- Checking the bowl for damage

- Checking the bearings for lubrication

- Function test of the safety devices

- Functional test & test run of the system