Multi-stage centrifugal extractors - Centrifugal force

Centrifuge | liquid-liquid | Series: BXP

Rousselet Robatel single-stage centrifugal extractors are used in the pharmaceutical, fine chemical, food and nuclear industries.

These single-stage centrifugal extractors, are also known as centrifugal contactors, ring centrifuge contactors or liquid/liquid extraction centrifuges.

Functional description

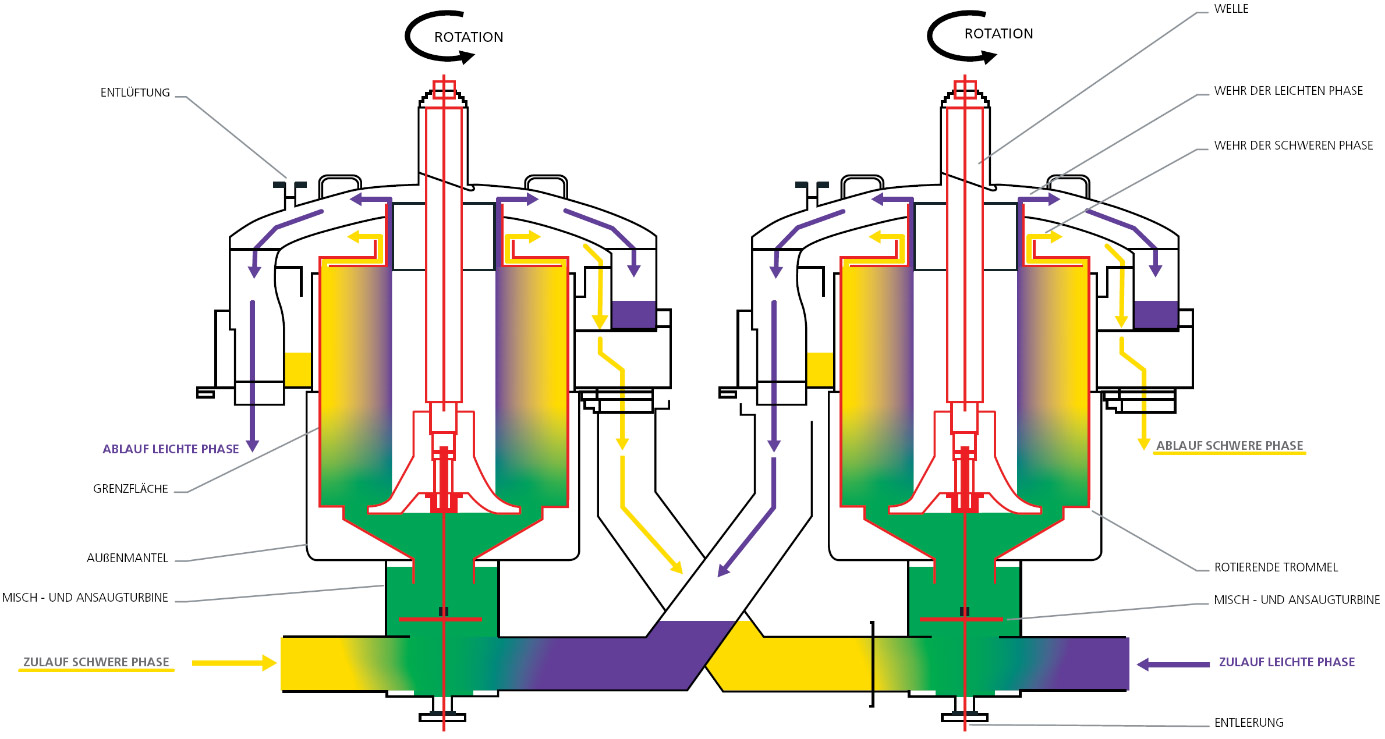

In centrifugal extractors, the phase to be extracted, which contains one or more solvates, and an immiscible solvent with a different density are fed into a mixing chamber located in the lower part of the device.

With the help of a rotating disc, the immiscible liquids are mixed to form a dispersion (green on the diagram). The liquids are separated by centrifugal force. The heavy phase is thrown against the wall of the drum, the light phase is positioned in the middle area of the drum.

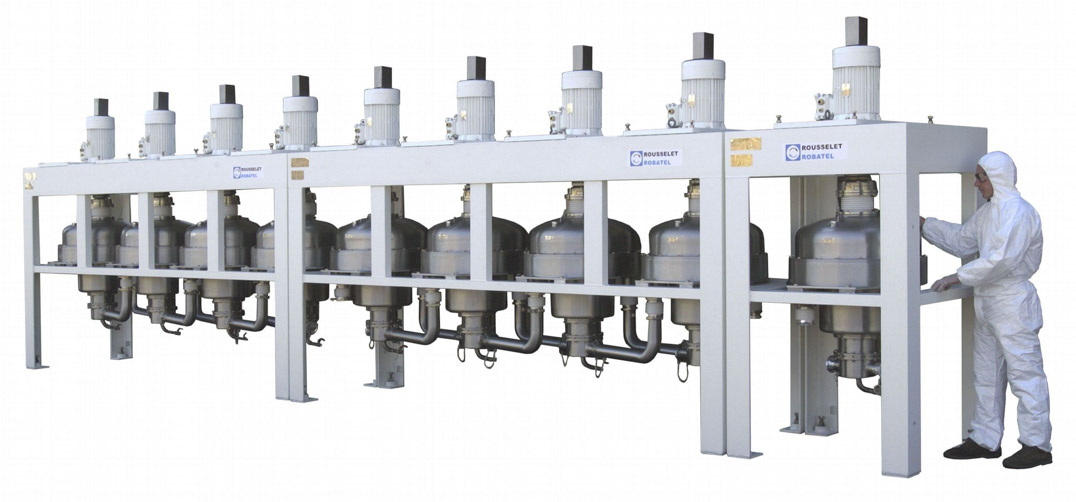

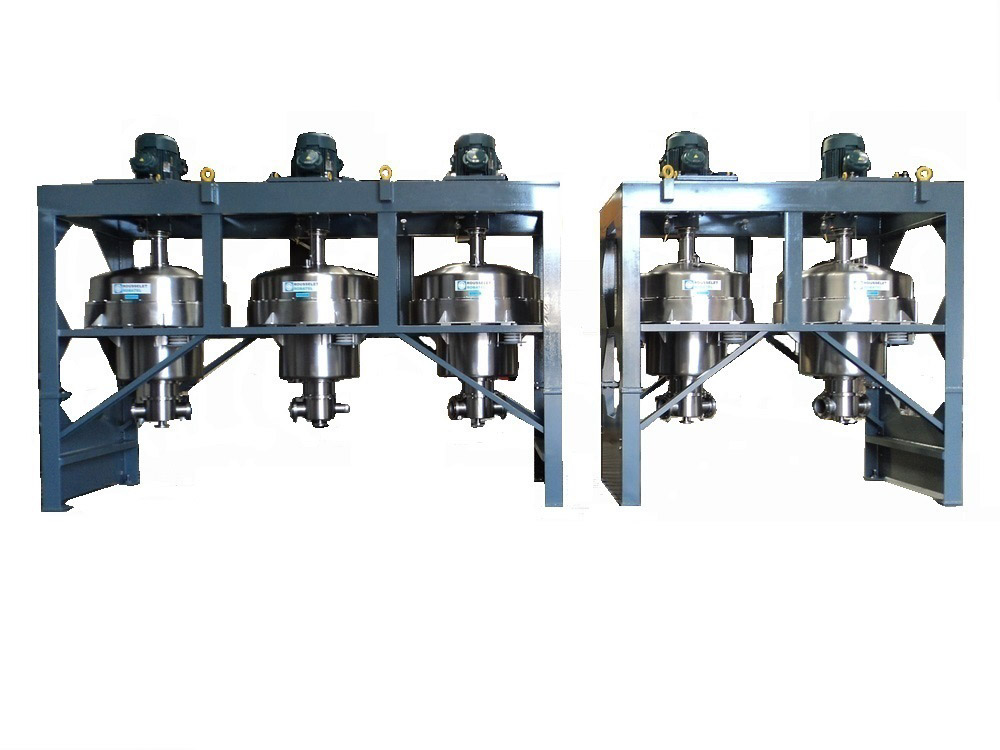

In extraction processes that require several successive stages, the single-stage extractors are connected in series or set up as batteries. One unit corresponds to each theoretical stage. In this case, the two liquids flow into the batteries in countercurrent.

Delivery pumps between the extractors are superfluous. The external connection lines allow the liquids to be transferred from one extractor to the other, or to be diverted from the process (main extraction, washing or re-extraction), as required. Optimum flexibility is thus guaranteed.

Advantages

- Direct drive of the reel by axial motor

- No bearing in the lower part (process zone)

- « All PVDF » version for corrosive products (exclusive to ROUSSELET ROBATEL)

- CIP device as option

- Special finishing of surfaces for pharmaceutical applications on request

- The equipment is suitable for both cyclic and continuous operation

- Very short contact and dwell time

- Use of small amounts of solvent

- Efficient separation accelerated by centrifugal force

- Wide range of agitator discs

- Turbines in special design for sensitive applications

- Autonomous operation, no monitoring required

- Strong extraction results in compact units with small footprint

- High extraction performance due to optimal mixing of the phases

- Each extractor corresponds to a theoretical extraction stage

- Rapid achievement of chemical equilibrium

- Permanent circulation of the heavy or light phase

- Use of the centrifuge as extractor or phase separator

- These extractors can be combined into batteries (without intermediate pumps) to correspond to the required number of stages

Application examples

PHARMACY: Purification of active ingredients (e.g. antibiotics).

CHEMISTRY: Washing (e.g. polymers)

- Extraction (e.g. acetic acid)

- Waste water treatment (e.g. phenol extraction from aqueous phase)

PARACHEMISTRY: perfumes, aromas, essential oils...

FOOD INDUSTRY: Purification of food components (e.g. carboxylic acid)

HYDROMETALLURGY: separation or purification (e.g. precious metals)

Technical data of the stainless steel BXP

ROUSSELET ROBATEL liquid-liquid centrifugal extractors can be made of various materials. Stainless steel W.-No. 1.4404, W.-No. 1.4539, Hastelloy C or special alloys (on request and subject to mechanical compatibility). As extractor version, the centrifuges can be mounted on separate or common frame and connected by hoses.

| Type | Reel ⌀ (mm) | Useful volume (L) | Rotation speed (U/min) | G-number | Nominal throughput (l/h) | Engine power (kW) |

|---|---|---|---|---|---|---|

| BXP 012 | 12 | 0,0022 | 10.000 | 671 | 0,002 | 0,025 |

| BXP 025 | 25 | 0,019 | 8.000 | 894 | 0,01 | 0,041 |

| BXP 040 | 40 | 0,11 | 3.600 | 290 | 60 | 25 |

| BXP 080 | 80 | 0,3 | 3.600 | 580 | 140 | 0,12 |

| BXP 190 | 190 | 4,2 | 3.600 | 1.377 | 3.500 | 1,1 |

| BXP 320 | 320 | 17 | 3.600 | 2.318 | 7.000 | 5,5 |

| BXP 360 | 360 | 29 | 3.600 | 2.608 | 12.000 | 5,5 |

| BXP 520 | 520 | 110 | 1.750 | 890 | 30.000 | 7,5 |

| BXP 800 | 800 | 320 | 1.300 | 756 | 75.000 | 18,5 |

Technical data of the PVDF BXP

Some ROUSSELET ROBATEL centrifuges (liquid-liquid) are made of PVDF for all parts in contact with the product. This design allows the units to be used for corrosive products to which a metal design would not be resistant. As an extractor version, the centrifuges can be mounted on separate or common frames and connected by hoses.

| Type | Reel ⌀ (mm) | Useful volume (L) | Rotation speed (U/min) | G-number | Nominal throughput (l/h) | Engine power (kW) |

|---|---|---|---|---|---|---|

| BXP 040 P | 40 | 0,11 | 3.600 | 290 | 60 | 25 |

| BXP 130 P | 130 | 1,3 | 1.750 | 223 | 700 | 0,37 |

| BXP 130 PL | 130 | 1,9 | 1.750 | 223 | 1.000 | 0,37 |

| BXP 210 P | 210 | 5,6 | 1.750 | 360 | 3.500 | 0,75 |

| BXP 210 PL | 210 | 7,8 | 1.750 | 360 | 4.800 | 0,75 |

| BXP 360 P | 360 | 29 | 1.170 | 275 | 14.000 | 2,2 |

| BXP 360 PL | 360 | 39 | 1.170 | 275 | 18.000 | 2,2 |

| BXP 460 P | 460 | 80 | 870 | 195 | 28.000 | 3,6 |

| BXP 620 P | 620 | 175 | 580 | 117 | 60.000 | 3,6 |